Steven Merrifield created this oscilloscope probe board:

HF Differential Probe

Here is a basic high frequency differential probe ideal for monitoring signals such as RS-485, CAN, MIL-STD-1553 and so on

sjm has shared the board on OSH Park:

Steven Merrifield created this oscilloscope probe board:

Here is a basic high frequency differential probe ideal for monitoring signals such as RS-485, CAN, MIL-STD-1553 and so on

sjm has shared the board on OSH Park:

The 2016 Hackaday SuperConference is coming. Now is the time to submit your proposal for a talk or a workshop at the world’s greatest conference about hardware creation. The SuperCon is an unparalleled opportunity to present on a deeply technical level where you can be certain everyone in the audience is following. All of those…

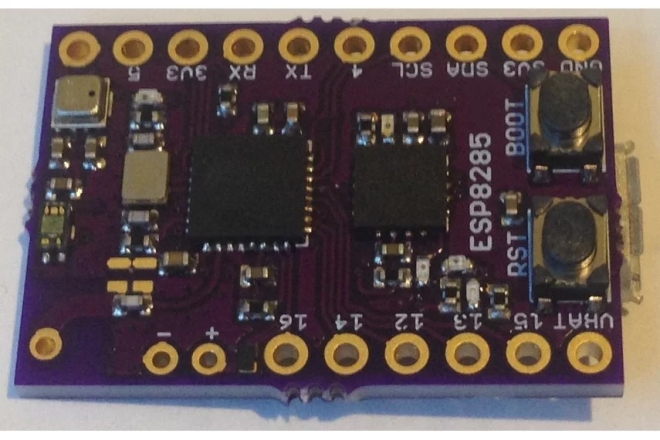

Kris Winer writes on Maker.io about his new design:

This is a small development board for the ESP8285 (ESP8266 plus 1 Mbyte embedded SPI flash memory) which includes an FTDI FT230X USB-to-serial converter so Arduino programs can be flashed via the USB Micro-B connector. The board has a MAX1555 LiPo battery charger, a 3.3 V MIC5528 LDO supplying 500 mA for plenty of power, has reset and boot buttons for easy programming, has a blue led on GPIO15, green led for power on, red led for charging indication, and yellow and orange leds for RX/TX.

Available for $24.95 on Tindie.

PeskyProducts has shared the board on OSH Park:

Don’t worry, the rhythms themselves aren’t random! That would hardly make for a useful drum machine. [kbob]’s creation does have the ability to randomly generate functional rhythms, though, and it’s all done on a breadboard. The core of this tiny drum machine is two Teensy dev boards. One is an FM synth tuned to sound like drums,…

Slowly, very slowly, the time when we don’t subject embedded beginners to AVRs and PICs is coming. At a glacial pace, FPGA development platforms are becoming ever more capable and less expensive. [Eric Brombaugh] has been playing around with both ARMs and FPGAs for a while now and decided to combine these two loves into…

Tritium, or 3H is an isotope of hydrogen which has been used as everything from radiolabel in analytical chemistry to a booster to kickstart the chain reaction of nuclear weapons. Lately tritium’s most common use has been in key chains and jewelry. A small amount of tritium is stored in a phosphor coated glass tube.…

via TritiLED Lights Up The Night, Doesn’t Make You Glow — Hackaday

[Written by OSH Park engineer Jenner Hanni on Wickerbox Electronics]

The STM32F4-Discovery development board has columns of male pin headers. I made a breakout board since you can’t plug the dev board into a breadboard, since the two columns on each side will short, and I’ve found the female-to-male jumpers to be unreliable. I made up a breakout board but it’s sadly cost prohibitive at $40 for three boards. Still a quick, fun project.

I’ve open sourced and shared the project at OSH Park.

I started with Jason Lopez’s STM32F4-Discovery Board Eagle schematic and footprint.

For the first test, I placed all the traces on the bottom of the board. Bottom in the layout here is blue. This made it possible to route a breakout board on the PCB router at Portland State’s Lab for Interconnected Devices. I didn’t want to have to plate all the via holes by hand to solder on the bottom and use traces on the top. Been there, done that, not interested. There are 200 vias on this board!

It worked fine, but there’s no silk and I’d really like a better looking board. I uploaded the now-verified Eagle .brd file to OSH Park. Of course, since OSH Park charges $5/square inch for three boards, it was $53.05 for three! Way out of my price budget. Luckily, you can submit designs where two completely separate boards are sitting next to each other on one .brd file.

This is the OSH preview with a cost of $33.95 for three. OSH Park charges for the smallest rectangle that encompasses your design, and you have to leave 100 mils between boards so the fab can mill it out.

It’s still significant, at about $10/board, but I can live with that. The 2×25 and 1×25 female headers also added up. Looks great, though.

The design files are available at the Github repository, and the boards can be ordered for $33.95 for a set of three from OSH Park.

I used these Sullins female headers:

Qty 4 of PPTC251LFBN-RC 1×25 0.1″ for $1.41 each

Qty 2 of SFH11-PBPC-D25-ST-BK 2×25 0.1″ for $2.89 each.

I’d bet you could search on Digikey or Mouser and find a cheaper equivalent.

This project is licensed under CERN’s Open Hardware License v1.2.

[Written by OSH Park engineer Jenner Hanni on Wickerbox Electronics]

Portland State University’s Maseeh College of Engineering and Computer Science runs an innovation program that awards small thousand-dollar grants to students working on interesting projects. In 2011 there were a handful of GPS-related projects that needed a way to work directly with the raw I/Q data coming from the GPS satellites before any processing or correlating had been done.

Commercial off-the-shelf GPS receivers are cheap and ubiquitous but they don’t expose that data. One of my mentors, Andrew Greenberg, developed an open source GPS receiver for his Masters thesis (PDF) in 2005 and suggested I take a look at doing the same thing with current hardware. I said I would if he would help, so together we built a board, built a revision, and are in the process of figuring out what modifications will be needed for a third.

The board isn’t a full GPS receiver. Instead, it’s an “RF front end” board that has a MAX2769 Universal GPS Receiver chip to read the GPS signals and pass them out over something that looks a lot like SPI but isn’t. We chose to place an STM32F407 microcontroller running the ChibiOS embedded operating system on the board to support streaming the data out over Ethernet and USB. We exposed the raw pins over a header between the MAX2769 and STM32F407 to allow a user to skip the microcontroller entirely. We also included an SD card to log the data.

The board does not currently support a battery so it must be powered over USB or Ethernet at all times.

This project is open hardware and software licensed under the 3-clause BSD license and maintained on the Portland State Aerospace Society’s Github account. You can find the bill of materials and Eagle schematics at psas/gps-rf-board and the software as part of psas/stm32.

It’s been a big group effort in the push to get it talking; Andrew, K, Theo, and Kenny at least have helped out with software and modwire soldering, and I might have missed someone.

The board has four layers and was ordered from OSH Park.

We can power the board from Rocketnet Ethernet (up to 20V) or over USB (about 5V) so we used an LMZ12001 switching regulator with an input voltage range from 4.5V to 20V to output 3.3V for the digital side of the board. We then used two ultra-low noise MAX8510 LDO linear regulators to provide 2.85V on separate digital and analog supply lines for the RF side of the board.

The MAX2769 is a tiny 28-pin universal GPS Receiver with a 1.4dB noise figure. The datasheet says we don’t need external SAW filters but we used them anyway. The chip has two LNA inputs and the eval kit is set up for to support both passive and active antennas. We used the MAX2769 Eval Kit as a reference but it was a particularly difficult schematic to work with.

Our board has a single antenna attachment point with a couple of optional circuits that the user chooses by where you populate capacitors and resistors. Option #1 is whether or not to have an LNA1 and its ANTBIAS-pin power circuit. Option #2 is whether to put into LNA1 or LNA2 on the chip.

We use a 100-pin ARM Cortex-M3 STM32F407 running the Portland State Aerospace Society’s version of ChibiOS to program the MAX2769 and to support USB, Ethernet, and an SD card. We also break out raw data signals at pin test points.

Ethernet requires the Portland State Aerospace Society’s Rocketnet connector for programming, data streaming, and power.

A micro-USB connector is available for programming, data streaming, and power.

The micro-SD card is available for data logging.

The serial breakout is two 1×11 0.1” headers which we also used for debug. We ran traces between the two breakouts because we were unsure about some of the pinouts from the MAX2769 and wanted to be sure we could cut traces and easily run modwire.

This is the board installed on the avionics module that carries the flight computer, sensor packages, and battery packs. The green board on top is the commercial Crescent GPS unit. The purple board down below is the JennerGPS. They’re both connected to the splitter in the middle, which runs off to the cylindrical patch antenna on the skin of the rocket.

The v2 board was flown on the Portland State Aerospace Society’s LV2.3 airframe for Launch 11 on July 20th, 2014, in Brothers, Oregon, to an altitude of 15,000 feet. The hardware was complete but the software on the board was not entirely ready for launch and, anyway, the entire GPS system failed so no data was retrieved.

More information on the launch is available at the PSAS Launch 11 page.

Launch 12 in 2015 carried a third version of the GPS RF front-end board designed and laid out by Andrew Greenberg, and GPS packets were successfully captured.

The Github repository has all the schematics. The current version described here is v2, but the newest version is v3. PSAS welcomes collaboration, but you’ll wan to contact PSAS directly through the main GPS repository. The best way to contribute is to come to a meeting.

It was super helpful to reference Swift Navigation’s Piksi GPS Receiver which uses the MAX2769 chip with an STM32F407 and FPGA.

The first version of this board was funded by the MCECS Innovation Program.

This project was released under the BSD “3-clause” license. See here for more information.

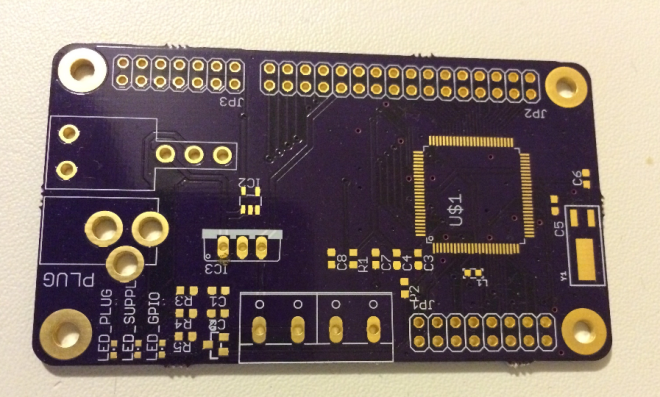

John Boyd created simple controller for RGB LED panels with the Texas Instruments MSP432 ARM microcontroller:

I have managed to get it working without issue at 60 FPS [..] I think I could push to above 100 FPS.

The challenging part of this project was designing the firmware in a way to leverage all of the MSP432 peripherals to reduce the computational requirements for the CPU.

The hardware design files and firmware source code are hosted on GitHub:

[Written by OSH Park engineer Jenner Hanni on Wickerbox Electronics]

This was a collaboration with Tom Hogue (tz89 from the Venture Rider forum) to translate his prototyped design onto a printed circuit board. He’s done all of the software; my contributions were entirely in hardware.

The Carb Sync Shield monitors the up to six carburetors and displays the vacuum pressure in realtime on an LCD display so the user can make adjustments to the air/fuel mix in each cylinder.

There’s an additional RPM feature that will be useful to set and monitor the idle speed on bikes that don’t have a tachometer.

The kit can be assembled by a novice using a basic soldering iron. The pressure sensors have extra-large surface mount pads and all other components are through-hole.

The shield is compatible with both the Arduino Uno v3 and the Bluetooth-capable RedBear Blend v1. It displays the RPM calculated from each of up to six simultaneous 3.3V or 5V pressure sensors on an LCD display which can be mounted directly or connected with the rainbow jumpers as shown above.

The board draws power from the carrier Uno or Blend board, which in turn can run off a 9V battery or a USB plug. The blue trim potentiometer controls the brightness of the LCD so it’s visible indoors or outdoors. The large switch sets the analog pressure sensor reference voltage to 3.3V or 5V. In the final version of the board, the switch is replaced with a 3-pin header and jumper cap.

Three digital I/O lines are broken out along with dedicated 5V or 3.3V pins to support extra sensors. It’s up to the user to match the sensor voltage on the digital line to the expected operating voltage of the Uno or Blend.

We had the boards fabricated through OSH Park, a local batch PCB service based in Oregon, and did a successful test in early November on Tom’s bike.