Jo Hinchliffe writes on the Tindie blog:

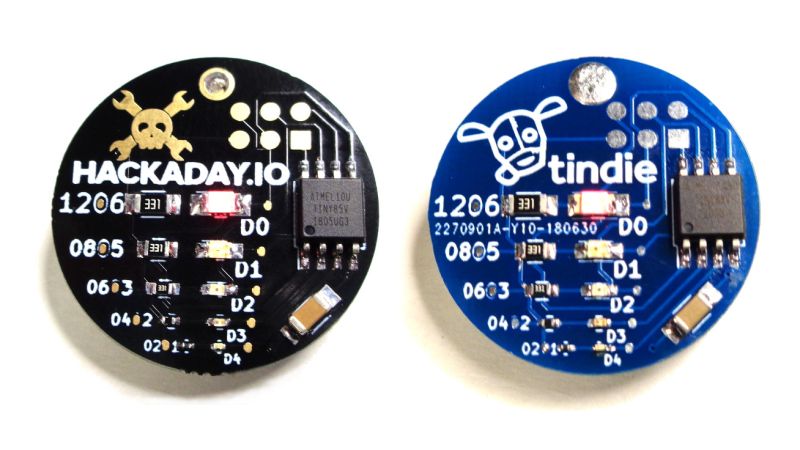

ATtiny LED Letter Keychain Kit

If you have tried your hand at soldering and want to progress to soldering with surface mount devices (SMD), this LED keychain kit might be just the ticket!

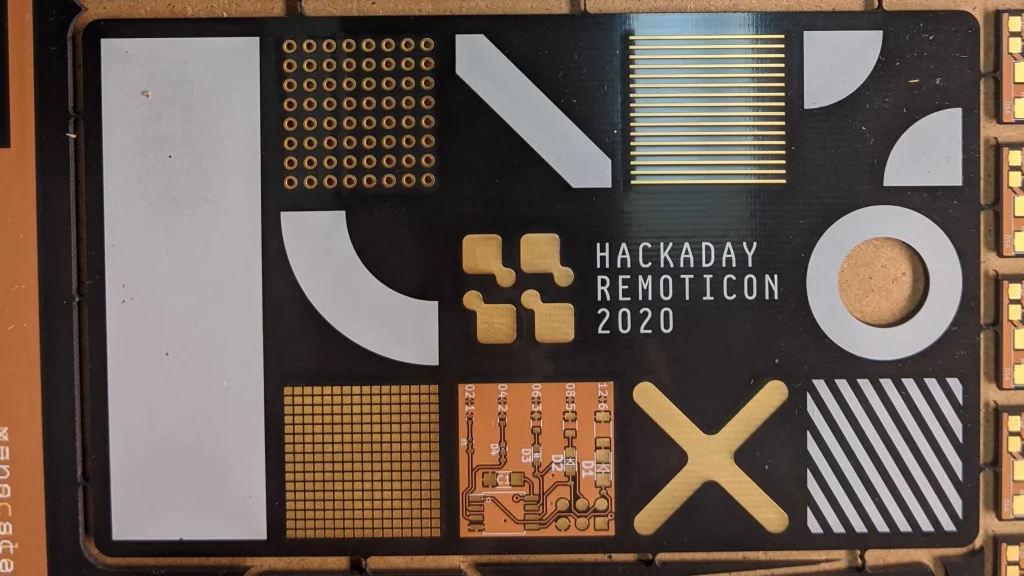

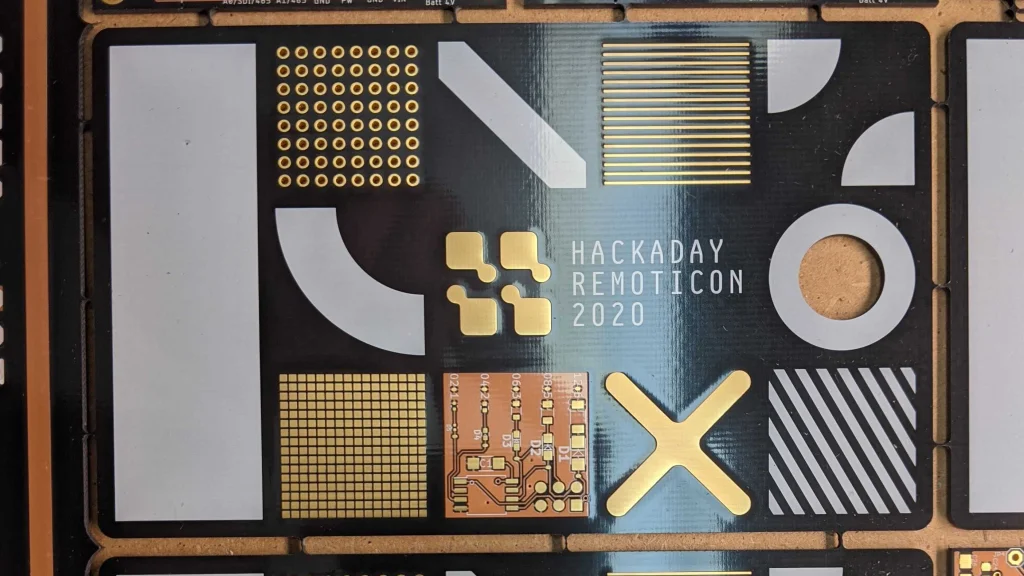

The kit is comprised of a tiny PCB featuring a grid of pads onto which you solder some of the 15 SMD LEDs supplied. You can use as many or as few as you need to make your chosen letter or icon. Arranged as 3 columns of 5 LED’s you can make any letter you require. The ATtiny micro controller can be supplied pre-flashed with the project code and once assembled the keychain has four display modes, all on, slow blink, fade and fast blink. Of course the code is provided in the documentation and you could always create your own patterns for the device.

You get a choice of LED colour when ordering and we think this is a great way to practice your SMD soldering or a nice kit to put together as a gift for someone.