Yes, we’re still in a pandemic and yes, these types of events are still happening over videoconference and not in meat space. But you know what? That means that so many more people have the opportunity to show up and show off their hacks! As long as 1 PM PDT is within your personal uptime, that is. Maybe you can make an exception if not?

Here is your link: the summer edition of Bring a Hack with Tindie and Hackaday will take place on Thursday, August 5th at 1:00 PM Pacific Daylight time (that’s 4pm EDT | 9pm BST/CET). Choose your gnarliest hack of late and go register for the event, which will be held on the Crowdcast video chat platform this time around.

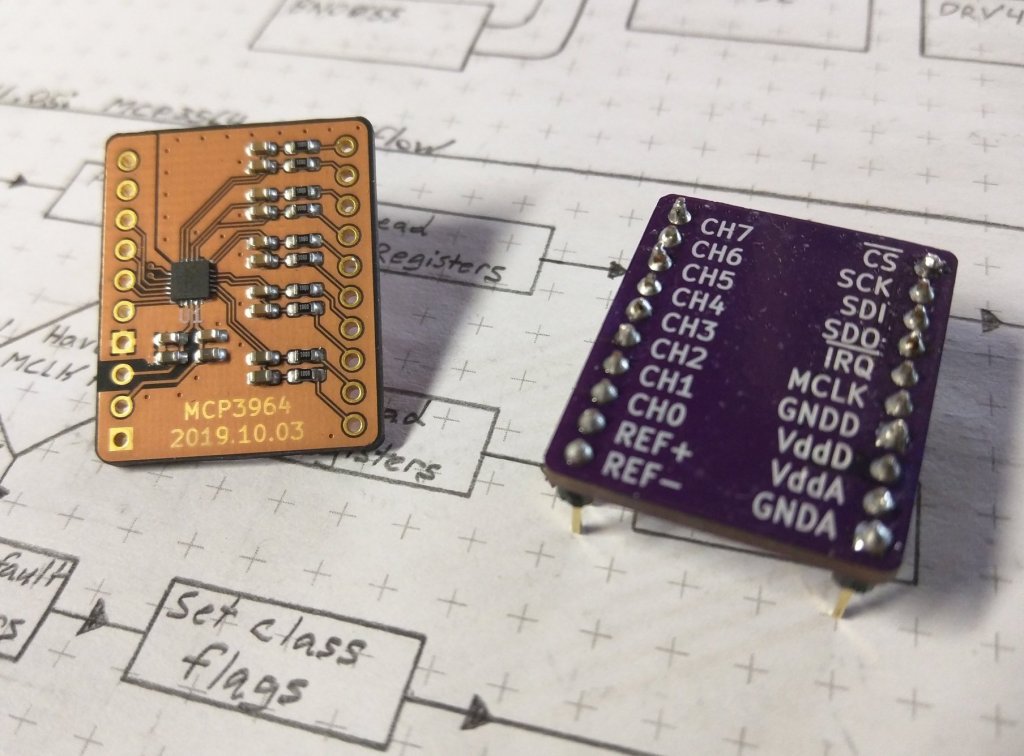

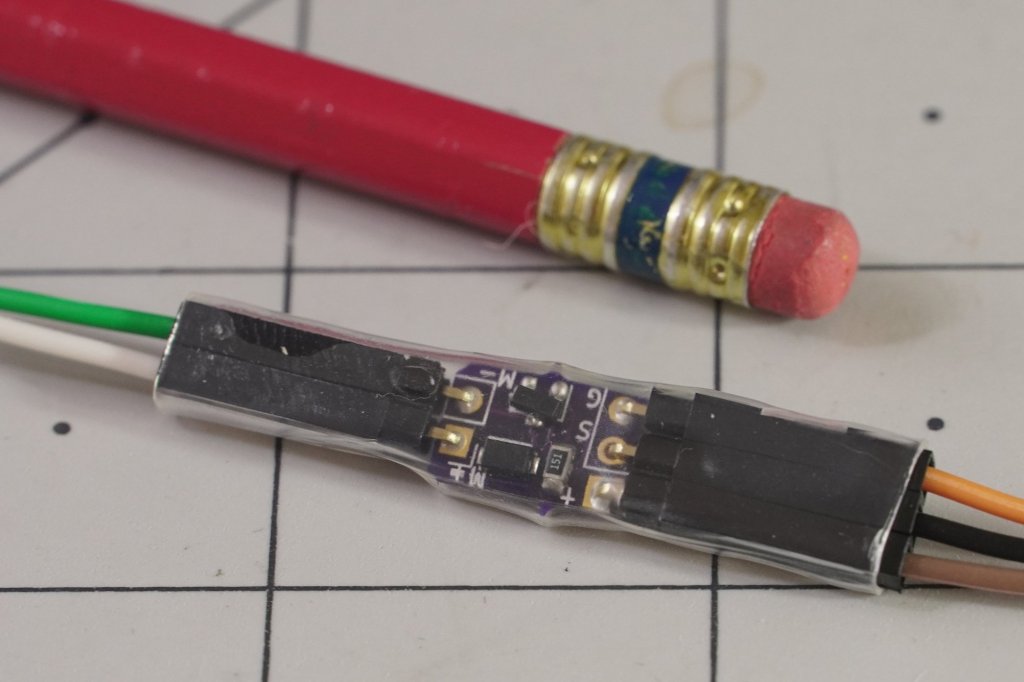

The remote Bring-A-Hack held way back in April was packed with awesome people. Now is your chance to join in! You all have awesome projects from the last few months (we’ve seen a lot of them on these very pages), so come show them off to the hacker elite from around the globe. You know the deal: it really doesn’t matter what level your project is on, so don’t worry about that. As long as you’re passionate about it, we’d love to see it and hear all about the problems you had to overcome and yes, even the mistakes you made. You never know what knowledge you might have that can push someone else’s project over the finish line.