From Benjamin Blundell:

Field programmable gate arrays, or FPGAs are wonderful little devices. In a nutshell, they are a whole load of logic blocks, wired together with interconnects. These logic blocks can be wired up however you like, to create simple, or complicated circuits. Anything from a simple XOR gate, to a CPU, to an entire system (if you have enough money to buy the biggest ones). Think of them as a big box of lego bricks that you can combine in any way you want to create any kind of digital circuit.

FPGAs have been used in many applications – emulation of older systems being one. The MiSTer is one such example. Jeri Ellsworth’s C-One is another. But really, FPGAs are found everywhere. They are quick, robust and adaptable to most situations.

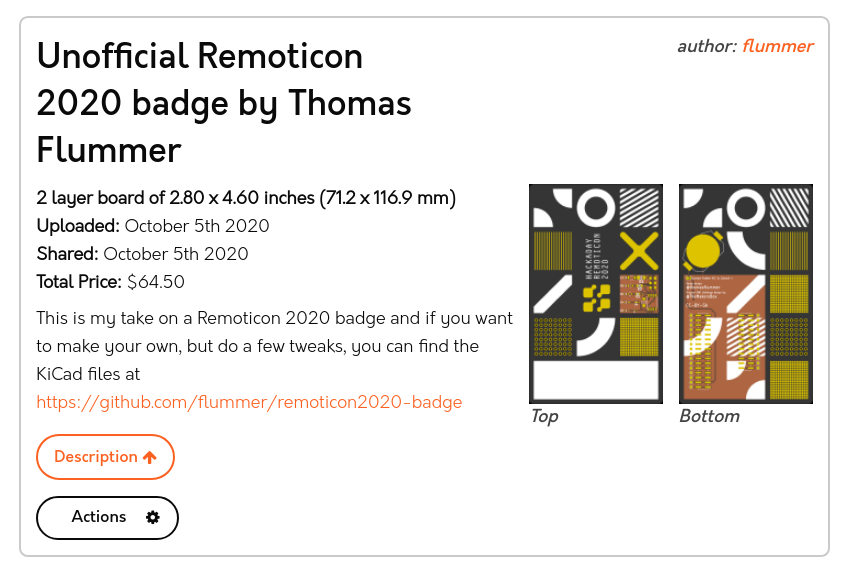

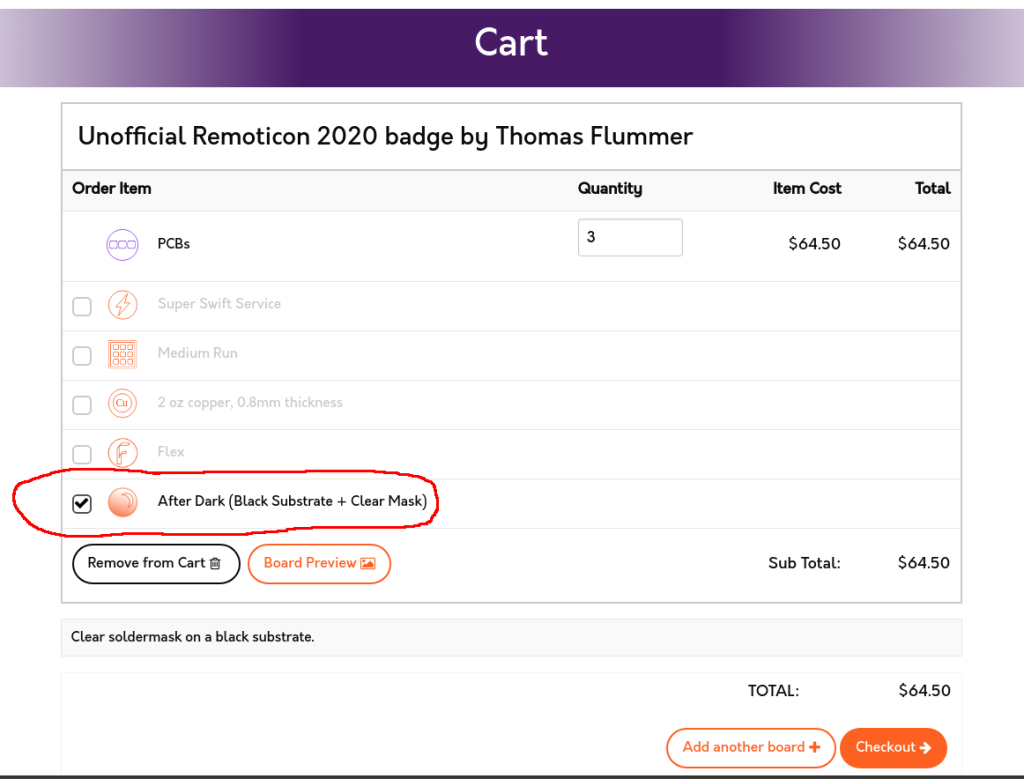

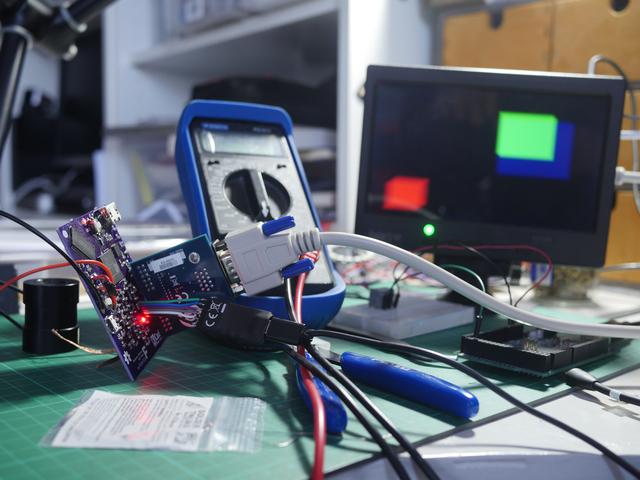

My friend Will runs the Project-F website where he investigates all things FPGA. I’ve been helping out by building some boards for us, and this is one of the first. I’d like to show you all how I went about building one of our early prototypes, the triumphs and pitfalls and hopefully inspire folks to give it a go themselves.