Would you believe that you can take a cheap 3D printer and easily convert it into a full function pick and place machine to help assemble your PCBs? No? Well good, because you can’t. A real pick and place needs all kinds of sensors and logic to identify parts, rotate them, make sure everything is aligned, etc, etc. There’s no way you could just bolt all that onto a cheap 3D printer, and let’s not even talk about the lack of closed loop control.

But if you have a very specific use case, namely a PCB that only has a relatively large single part that doesn’t need to be rotated, [Connor Nishijima] might have a solution for you. He bought a $150 USD Monoprice Mini, and with the addition of a few printed parts, was able to build a machine that drastically cuts down the time it takes for him to build his LED boards. Best of all the modification doesn’t involve any permanent changes to the printer, he can just pop off the vacuum attachment when he wants to print something.

Month: July 2018

KiCad 6 development fundraiser

KiCad 6 Donation Campaign

The world needs a freely available tool for designing open-source hardware. Without it, designers do not have the freedom to share their work efficiently. KiCad is that tool, and you can help to develop it.

A stable release of KiCad Version 6 could become available very soon, so that everybody can profit from its enhanced features. With an extra 600 hours of expert development, this might become a reality!

Contribute to KiCad Version 6 with a donation and help us reach the goal of 600 hours of expert development that can make the new release available sooner than you think.

Twenty Power Harvesting Projects Headed to the Hackaday Prize Finals

The Academy Awards of hardware creation is going on right now! The Hackaday Prize is a challenge to you — yes, you — to create the next great piece of Open Hardware. It is simply incomparable to anything else, and we have the projects to show for it.

We wrapped up the Power Harvesting Challenge portion of The Hackaday Prize. Now we’re happy to announce twenty of those projects have been selected to move onto the final round and have been awarded a $1000 cash prize. Congratulations to the winners of the Power Harvesting Challenge portion of the Hackaday Prize.

via Twenty Power Harvesting Projects Headed to the Hackaday Prize Finals — Hackaday

KiCad 5: A New Generation

KiCad 5 – A New Generation

Almost a year after the release of KiCad 4.0.7, the KiCad development team is proud to present a new and improved KiCad 5.0 release!

The stable release version 5.0.0 is made from the stable 5.0 branch. KiCad binaries should be available now or in the very near future for download for Windows, macOS and Linux. See the download page for guidance.

Instructions for packagers can be found on the download page describing how to build from source . Below are also some packaging packaging related changes since the 4.0 releases. The official KiCad libraries have also seen a lot of improvement in management, style and consistency by the librarians. Read more about this on the new library section on the website.

Thank you to all developers, packagers, librarians, document writers, translators, and everyone else who helped make this release possible.

Belgrade Badge Hacks

We’re still coming off the Hackaday Belgrade conference right now. If you were there, you know it was the greatest hardware conference ever. If you weren’t there, you missed out. Sorry. (Make sure you get in on the Hackaday Superconference in November.)

One of the many highlights of the Belgrade conference was, of course, the badge. The 2018 Hackaday Belgrade Badge is a masterpiece of hardware with a 55-key keyboard, RGB TFT LED, speaker, and a BASIC interpreter.

This badge is a masterpiece of electronic design by Voja Antonic. Just to take one small example from the design, check out the placement of the buttons. Think the slightly rotated buttons that make up the keyboard is only a stylistic choice? It’s not; by carefully rotating each button, the legs of each switch can fit in between each other. It’s brilliant.

via Belgrade Badge Hacks — Hackaday

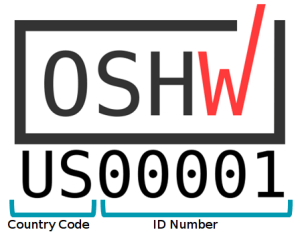

Open Source Hardware Certification Logo is Official

Michael Weinberg writes on the Open Source Hardware Association blog:

Open Source Hardware Certification Logo is Official

We at OSHWA are excited to announce that the OSHWA Certification process has an officially registered trademark. This registration will make it easier for OSHWA to prevent people from using the OSHWA Open Source Hardware Certification logo if they have not actually gone through the certification process. We hope this will give the community more confidence when they see the OSHWA certification logo on hardware out in the world.

Tindie Seller Projects in The Robotics Module Challenge

From Bradley Ramsey on Tindie blog:

Tindie Sellers Competing in the Hackaday Prize

Tindie Sellers Competing in the Hackaday Prize

The Robotics Module Challenge just wrapped up and last week we featured two of the twenty finalists who are also Tindie Sellers. Today let’s look at several other Tindie Sellers who got in the game with their own robotics module designs!

Tindie seller Citrus CNC Store is working on a low-cost automatic pick and place feeder and entered it into the robotics challenge. The pick and place machine is a valuable resource for building electronics.

The end goal here is to create a fully featured pick and place machine at a mid-range hobby 3D printer price point, with support for at least 20 automatic tape feeders and loop control of every motion related component. Check out this project on Hackaday.io.

Another Tindie seller who owns the proto-Phi Store is working on a modular design for a soft robotic gripper.

The design is for soft robotics fabrication and emphasizes the molds and subsequent actuators. The current method combines the softness of a silicone actuator and a 3D plastic exoskeleton.

Check out the project page for more details!

Supporting Our Tindie Sellers

These aren’t the only Tindie sellers participating in this year’s Hackaday Prize. Take a look at these other robotics projects from our talented makers:

- Morpheus 6DOF Robotic Arm – Adamjvr

- Nomadstep Modular Motor Controllers – Ulcek

- Compact Spectrometer – TleraCorp

- Airsoft Turret – ActualDragon

- Ares Modular PCB Robot – KitsForKids

- Xlidar Open Source LiDAR – JRodrigo

- Tote Robot Leg – Deshipu

Stay tuned for more updates on the finalists, and future modules in this year’s Hackaday Prize!

Maker Faire party at i3 Detroit this Saturday (7/28)

The i3 Detroit Maker Faire After Party has as always been one of the best parts of Maker Faire Detroit weekend!

Build Your Own Portable Arduino Soldering Iron

At this point you’ve almost certainly seen one of these low-cost portable soldering irons, perhaps best exemplified by the TS100, a pocket-sized temperature controlled iron that can be had for as little as $50 USD from the usual overseas suppliers.

via Build Your Own Portable Arduino Soldering Iron — Hackaday

Emotional Hazards That Lurk Far From The Uncanny Valley

From Roger Cheng on the Hackaday blog:

Emotional Hazards That Lurk Far From The Uncanny Valley

A web search for “Uncanny Valley” will retrieve a lot of information about that discomfort we feel when an artificial creation is eerily lifelike. The syndrome tells us a lot about both human psychology and design challenges ahead. What about the opposite, when machines are clearly machines? Are we all clear? It turns out the answer is “No” as [Christine Sunu] explained at a Hackaday Los Angeles meetup.

When we build a robot, we know what’s inside the enclosure. But people who don’t know tend to extrapolate too much based only on the simple behavior they could see. As [Christine] says, people “anthropomorphize at the drop of the hat” projecting emotions onto machines and feeling emotions in return. This happens even when machines are deliberately designed to be utilitarian. iRobot was surprised how many Roomba owners gave their robot vacuum names and treated them as family members. A similar eruption of human empathy occurred with Boston Dynamics video footage demonstrating their robot staying upright despite being pushed around.