From the Downing’s Basement blog:

Project 15: My Latest N64 Portable, Zelda Style!

I wish I could say that it hasn’t been two years since this project was commissioned…I also wish I could say this wasn’t the second time the job was completed…but if I didn’t have too, this beauty would have never existed. Kinda funny how that works.

But that said, after two years since the original agreement and a total remake of the original failure, Project 15 has come to light in the most beautiful portable console I’ve ever made. But not only has this been a technical achievement for me in many respects, but I’m very proud of the video I’ve made to accompany it.

You don’t have to scroll down very far in past posts to see what prompted this rebuild but at this point I can honestly say I’m glad it happened!

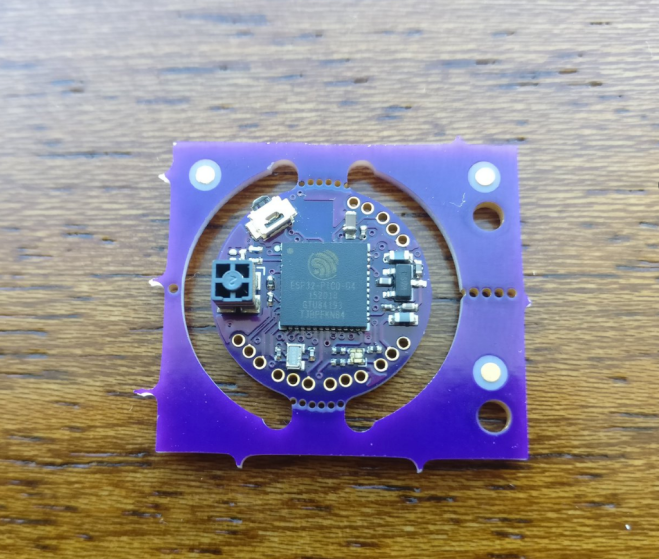

And on the subject of reliability, low volume FFC PCB’s have become available through services like OSH Park which have allowed some very time and space saving options that do wonders for the assembly.