Our Hackaday Prize Challenges are evaluated by a panel of judges who examine every entry to see how they fare against judging criteria. With prize money at stake, it makes sense we want to make sure it is done right. But we also have our Hackaday Prize achievements, with less at stake leading to a more […]

Uncategorized

Review: SMD Tweezer Meter or Tweezer Probes For Your Multimeter?

It’s remarkable how tiny electronics have become. Heaven knows what an old-timer whose experience started with tubes must think, to go from solder tags to SMD in a lifetime is some journey. Even the generation that started with discrete transistors has lived through an incredible shift. But it’s true, SMD components are tiny, and that…

via Review: SMD Tweezer Meter or Tweezer Probes For Your Multimeter? — Hackaday

Homebrew Pancreas Gets 30 Minutes of Fame

It is pretty unusual to be reading Bloomberg Businessweek and see an article with the main picture featuring a purple PCB (the picture above, in fact). But that’s just what we saw this morning. The story is about an open source modification to an insulin pump known as the RileyLink. This takes advantage of older…

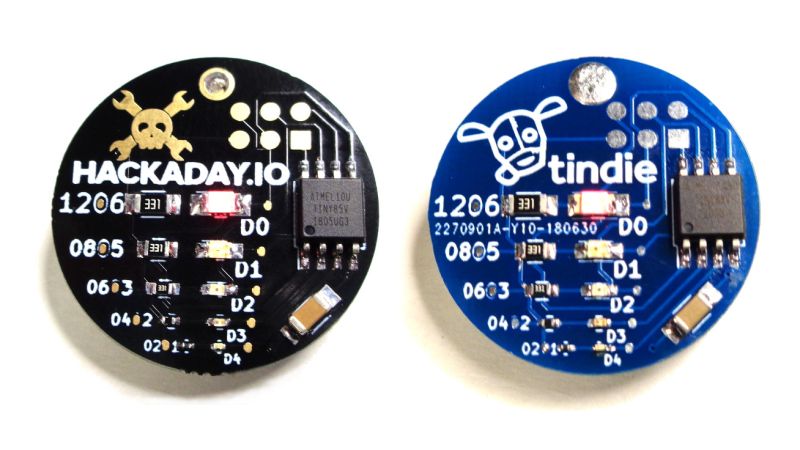

SMD Soldering Challenge Lands At DEF CON

Strap on the jeweler’s loupe and lay off the caffeine for a few days. You’ll need to be at your peak for the SMD Soldering Challenge at this year’s DEF CON… 367 more words

Teardown 2018 session videos

Teardown: Portland 2018 session videos

Between the talks, workshops, presentations, demos, and installations at Teardown 2018, there was a lot of intense information to absorb at once. Luckily, we were able to record some of the speakers doing their thing so attendees could reflect back and those who weren’t able to come physically are still able to participate. Videos are embedded in the sessions page. Here are shortcuts to each video:

A 3D-Printed Bowl Feeder for Tiny SMD Parts

[Andrzej Laczewski] has something big in mind for small parts, specifically SMD resistors and capacitors. He’s not talking much about that project, but from the prototype 3D-printed bowl feeder he built as part of it, we can guess that it’s going to be a pretty cool automation project.

Bowl feeders are common devices in industrial automation, used to take a big pile of parts like nuts and bolts and present them to a process one at a time, often with some sort of orientation step so that all the parts are the right way around. They accomplish this with a vibratory action through two axes, which [Andrzej] accomplishes with the 3D-printed ABS link arms supporting the bowl.

via A 3D-Printed Bowl Feeder for Tiny SMD Parts — Hackaday

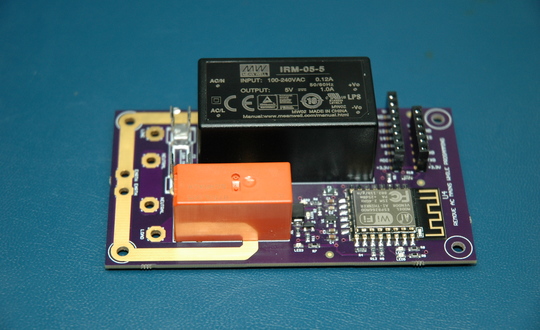

ESP8266 Power Switch

ESP8266 Power Switch

The DomCo Electronics, Inc. ESP8266 AC Power Switch is everything you need to get started with controlling AC mains from an ESP8266. We know dealing with AC can be intimidating for people at times and we wanted to simplify the process of making your own IoT device.

Everything you need to control a 100-240VAC 50/60Hz load is built right onto the board. Simply solder on a power lead and socket of your choice to the Power Switch and the on-board code can get you up and started in minutes. (We have a USA power tail and socket in the optional extras below.) No more needing to wire up an ESP board, a Wall wart, an IoT Power Relay (Power Tail), and a bunch of wires just to control your light or coffee maker.

Monoprice Mini Converted to Pick and Place (Kinda)

Would you believe that you can take a cheap 3D printer and easily convert it into a full function pick and place machine to help assemble your PCBs? No? Well good, because you can’t. A real pick and place needs all kinds of sensors and logic to identify parts, rotate them, make sure everything is aligned, etc, etc. There’s no way you could just bolt all that onto a cheap 3D printer, and let’s not even talk about the lack of closed loop control.

But if you have a very specific use case, namely a PCB that only has a relatively large single part that doesn’t need to be rotated, [Connor Nishijima] might have a solution for you. He bought a $150 USD Monoprice Mini, and with the addition of a few printed parts, was able to build a machine that drastically cuts down the time it takes for him to build his LED boards. Best of all the modification doesn’t involve any permanent changes to the printer, he can just pop off the vacuum attachment when he wants to print something.

Twenty Power Harvesting Projects Headed to the Hackaday Prize Finals

The Academy Awards of hardware creation is going on right now! The Hackaday Prize is a challenge to you — yes, you — to create the next great piece of Open Hardware. It is simply incomparable to anything else, and we have the projects to show for it.

We wrapped up the Power Harvesting Challenge portion of The Hackaday Prize. Now we’re happy to announce twenty of those projects have been selected to move onto the final round and have been awarded a $1000 cash prize. Congratulations to the winners of the Power Harvesting Challenge portion of the Hackaday Prize.

via Twenty Power Harvesting Projects Headed to the Hackaday Prize Finals — Hackaday

Tindie Seller Projects in The Robotics Module Challenge

From Bradley Ramsey on Tindie blog:

Tindie Sellers Competing in the Hackaday Prize

Tindie Sellers Competing in the Hackaday Prize

The Robotics Module Challenge just wrapped up and last week we featured two of the twenty finalists who are also Tindie Sellers. Today let’s look at several other Tindie Sellers who got in the game with their own robotics module designs!

Tindie seller Citrus CNC Store is working on a low-cost automatic pick and place feeder and entered it into the robotics challenge. The pick and place machine is a valuable resource for building electronics.

The end goal here is to create a fully featured pick and place machine at a mid-range hobby 3D printer price point, with support for at least 20 automatic tape feeders and loop control of every motion related component. Check out this project on Hackaday.io.

Another Tindie seller who owns the proto-Phi Store is working on a modular design for a soft robotic gripper.

The design is for soft robotics fabrication and emphasizes the molds and subsequent actuators. The current method combines the softness of a silicone actuator and a 3D plastic exoskeleton.

Check out the project page for more details!

Supporting Our Tindie Sellers

These aren’t the only Tindie sellers participating in this year’s Hackaday Prize. Take a look at these other robotics projects from our talented makers:

- Morpheus 6DOF Robotic Arm – Adamjvr

- Nomadstep Modular Motor Controllers – Ulcek

- Compact Spectrometer – TleraCorp

- Airsoft Turret – ActualDragon

- Ares Modular PCB Robot – KitsForKids

- Xlidar Open Source LiDAR – JRodrigo

- Tote Robot Leg – Deshipu

Stay tuned for more updates on the finalists, and future modules in this year’s Hackaday Prize!