Tom Fleet writes on Hackster about the latest open source board from the prolific Greg Davill:

Meet Obsidian Boa: This ItsyBitsy — with WiFi — Is What It’s All About!

No, we’re not branching out into nursery rhymes, but it’s too hard to pass up on the chance offered by the latest development from Hackster favorite Greg Davill!

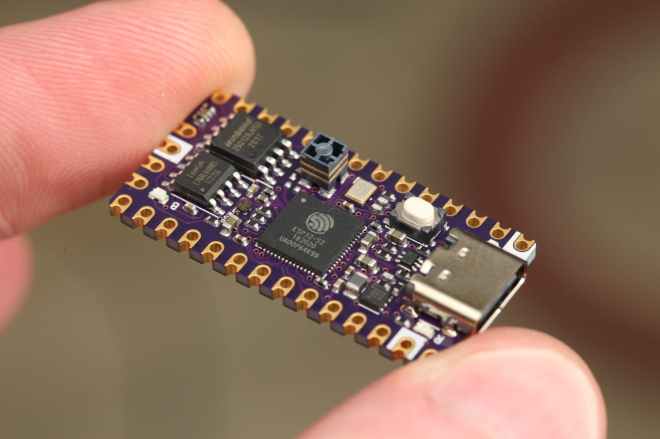

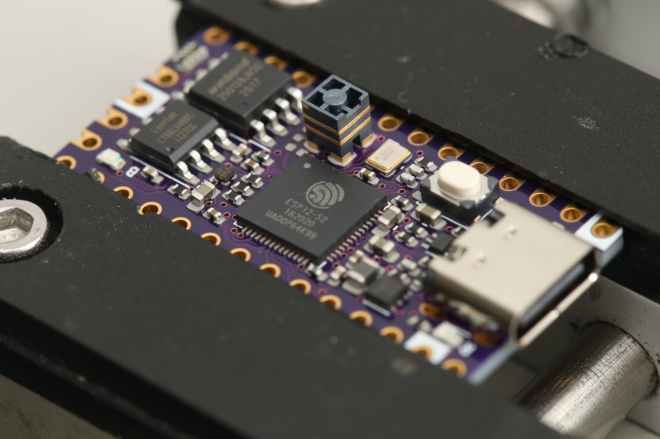

With the dust in his workshop only just settling (if that’s possible there…) from his successful OrangeCrab crowdfunding campaign, he’s gotten straight back to work, turning his sights from the Lattice ECP5, and setting them squarely on the Espressif Systems ESP32, with his latest creation — the ObsidianBoa!

While the above image is a render, the quality of Davill’s work shines through in both the the physical and the virtual world — some of his recent rendering work is hard to tell from reality.

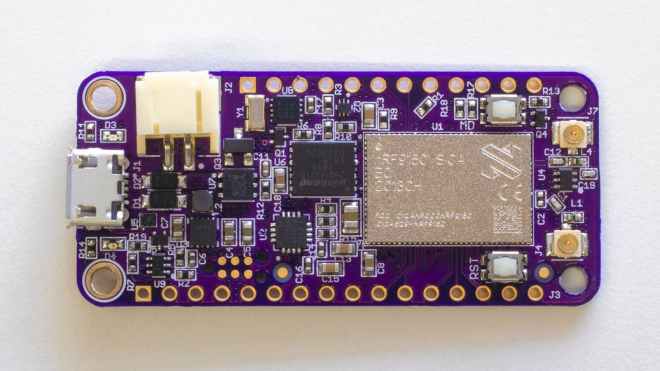

While there are a number of ESP32 development boards, there are few in such a diminutive form factor. The only one I know of, until now, has been the TinyPICO, from @unexpectedmaker. This is a fantastic board in it’s own right, and has been rightfully successful within the maker community.

Obsidian Boa has a few notable differences however, which might make it more suitable for certain applications.

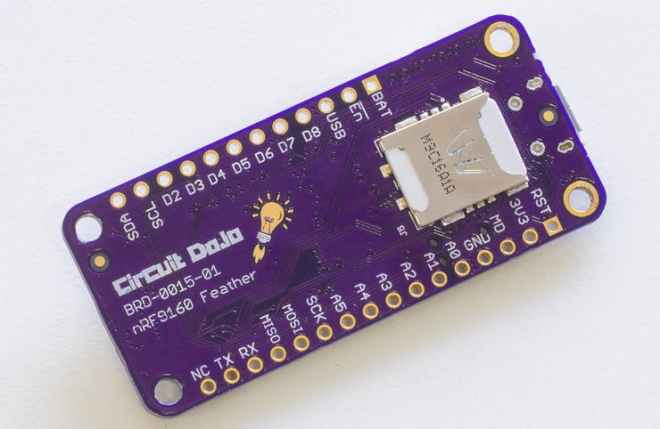

The first point of note is where we get the title of this article from. Not just a descriptive phrasing, ItsyBitsy is a lesser-heard-of form factor — and just as we all know boards in the Arduino R3 layout, or the hugely popular Feather form factor from Adafruit, ItsyBitsy started out life as yet another Adafruit board format, and was shortly thereafter realized as a baby brother alternative to the well known iCEBreaker FPGA boards.