QRP-Labs filter adapter for NanoVNA

I had a few QRP-labs lowpass filters and bandpass filters kits laying around and because I had nothing better to do this afternoon, I fired up the soldering station and assembled them. After that they need to be tested and tuned.

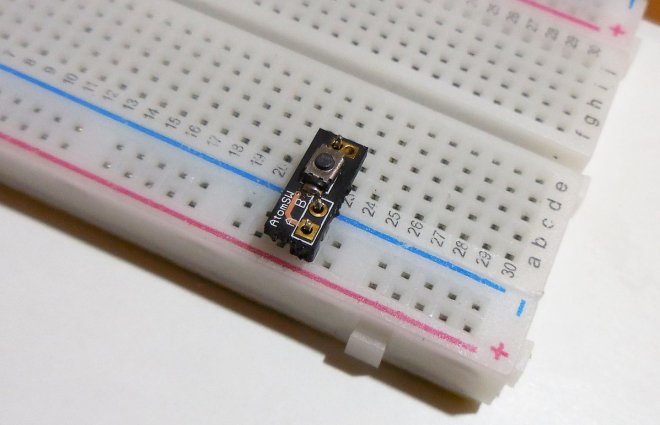

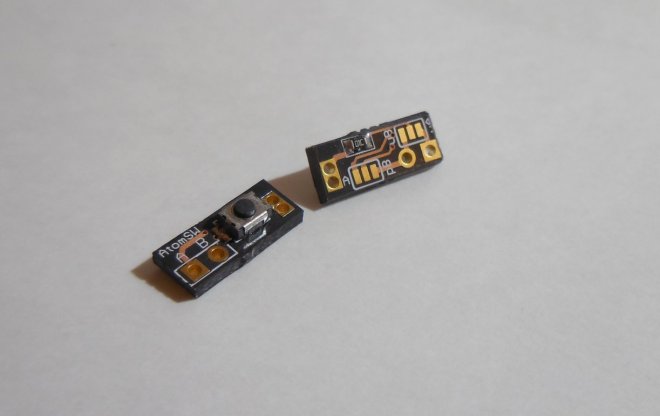

Owning a NanoVNA for a few months now (and hardly use it because for antenna stuff i use my RigExpert AA-600), I decided to use the NanoVNA for tuning the filters. So from some pieces out of my junkbox (a piece of double sided pcb, 2 sma chassis and a header cut in 2) I build this simple filter holder allowing me to test and tune the filters to my requirements.

Adding the 3D printed base plate, hooking it with my NanoVNA.

Doing the calibration routine.

And ready for testing.

As expected like the previous design. But now no aditional PCB for calibration.

Can only say that the purple on yellow looks cool 🙂

For those who want a adapter, checkout my ForSale page.