The Open Source Hardware Association (OSHWA) runs a free program that allows creators to certify that their hardware complies with the community definition of open source hardware. Whenever you see the certification logo, you know that the certified hardware meets this standard.

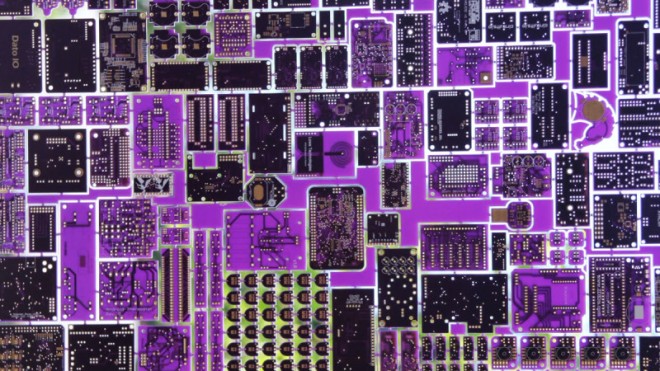

The certification site includes a full list of all of the certified open source hardware. Here is all of the hardware that was certified in April, which comes from the United States, Azerbaijan, India, Croatia, Germany, Poland, and Spain.

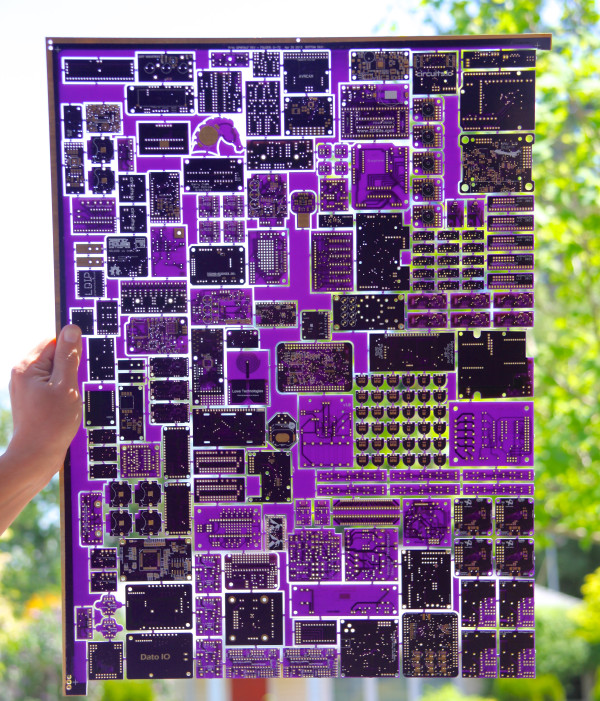

The OSHW community had been off to a strong start in 2020 with 54 projects certified in Q1. After February, we predicted here on Makezine.com that the certification program was on track for its strongest year ever. The surge in April has far surpassed our expectations with a total of 269 total projects certified last month alone, nearly twice that of 2019 in just one month.

Adafruit (All The Things)

Open Hardware leader Adafruit has dedicated a massive amount of time and effort towards certifying their back catalog of products. Hundreds have already passed certification at the time of writing this. We colloquially dubbed last month “Adafruit April” because of the sheer number of projects. In an interview with OSHdata, Founder Limor Fried takes us behind the scenes:

“Adafruit had certified some boards in the past to help support the effort. The barrier for certification for us was time. For us, the question was – do we stop everything and try to certify hundreds of boards? Or do we keep making open-source hardware? We choose to keep making open-source hardware with a goal to get it certified eventually, and/or wait for an API to automate the certification,” Fried explains.

Then COVID-19 happened. Adafruit has been running for 60+ days with no illnesses, no layoffs, no furlough, and no cut hours. They continued operations (after being deemed an essential business in NYC by Executive Order 202.6). Despite being busier than ever, this was also a time for reflection.

“It did occur to us that while our hardware is and always will be open-source, it was not certified. In March with the death rate increasing each day, as grim as it sounds, it was unclear what could happen to any of us in NYC or Adafruit. What is the best thing we can do for our community?” she and the team asked themselves.

That’s when Adafruit team members stepped up to take on the Herculean effort of submitting and certifying hundreds of products.

“We’re not going to make as much hardware during this time… And while some of the team was diverted for critical needs, we decided to spend time putting the hardware through the certification process so it’s clear our intentions for our hardware, it’s open source, forever, certified, no matter what. Dylan on our team led this effort and at this time 5/4/2020, Adafruit has certified 261 boards, with more to come, Adafruit is now 36.76% of all certified hardware. The phrase ‘never let a crisis go to waste’ was applied here to continue to be a good cause, a good company, and give all we can in every way.”

Read the full interview with Adafruit Industries Founder Limor Fried here.

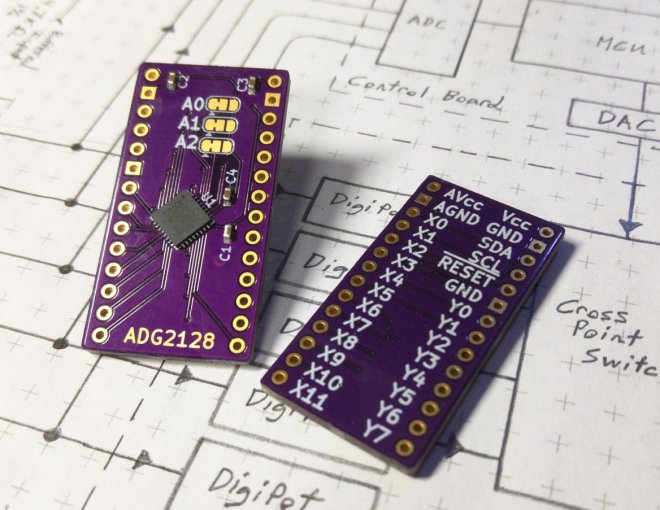

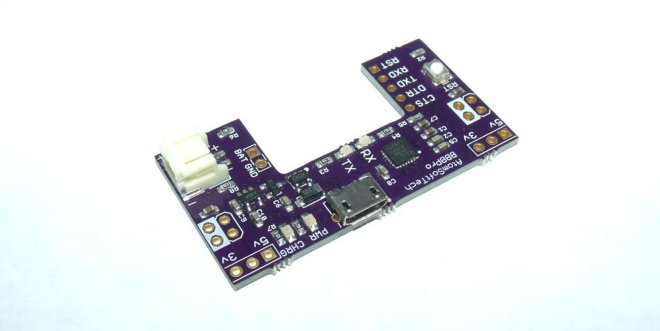

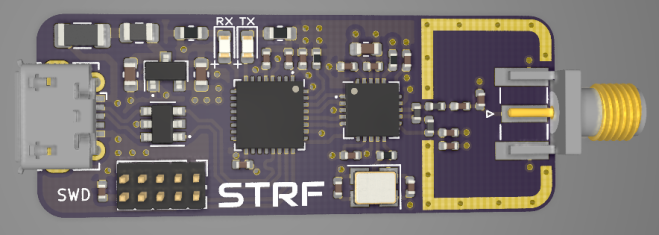

It’s impractical to go into detail about each of these projects — there are too many and this is but a simple blog post. Instead, we’d like to offer perspective on one of the certified projects: the Adafruit Trinket M0 (US000239). It’s a tiny microcontroller board built around the Atmel ATSAMD21 for use with CircuitPython and Arduino IDE. This small, affordable, and powerful platform is a great way to add interactivity to just about any project. For some context, we spoke with a pro.