Interested in hacking, discovering, and sharing hardware?

Teardown 2024 kicks off this Friday:

| When? | Friday 21st June to Sunday 23rd June 2024 |

| Where? | Beautiful Portland, Oregon at Lloyd Center Mall |

| What? | Talks, workshops, installations, demos and space to hack – check out last year’s line up |

| Who? | Anyone interested in hardware: engineers, designers, artists, educators or enthusiasts |

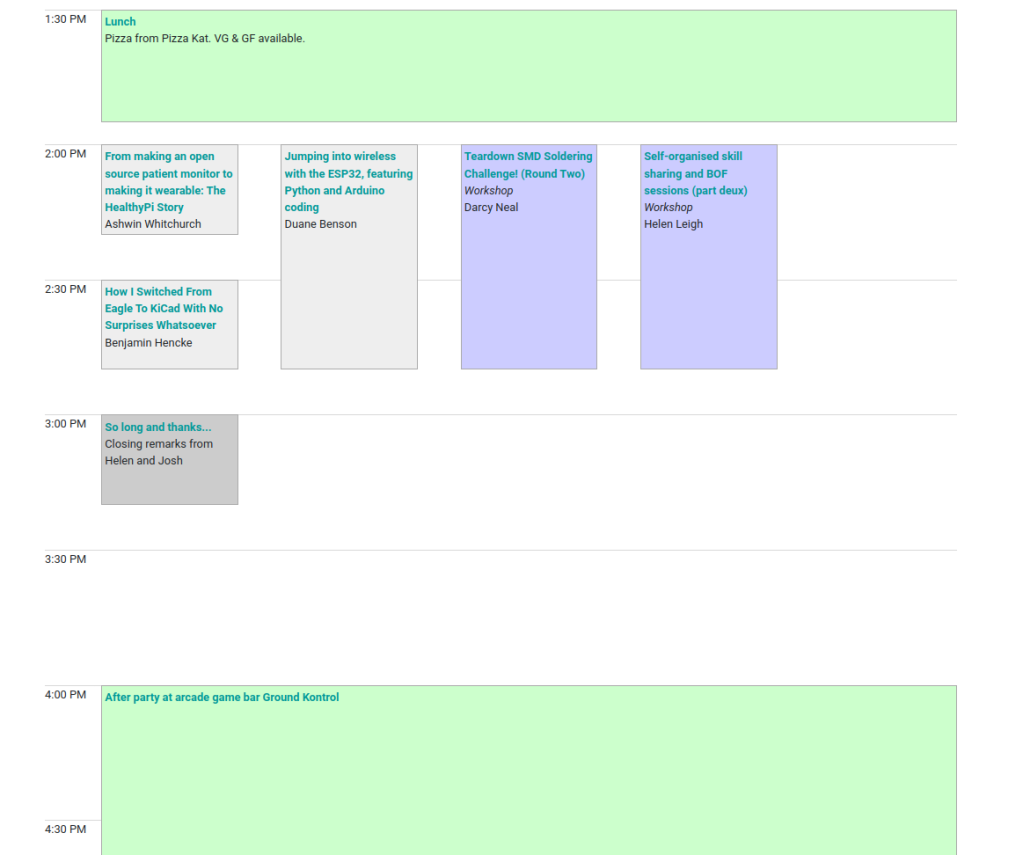

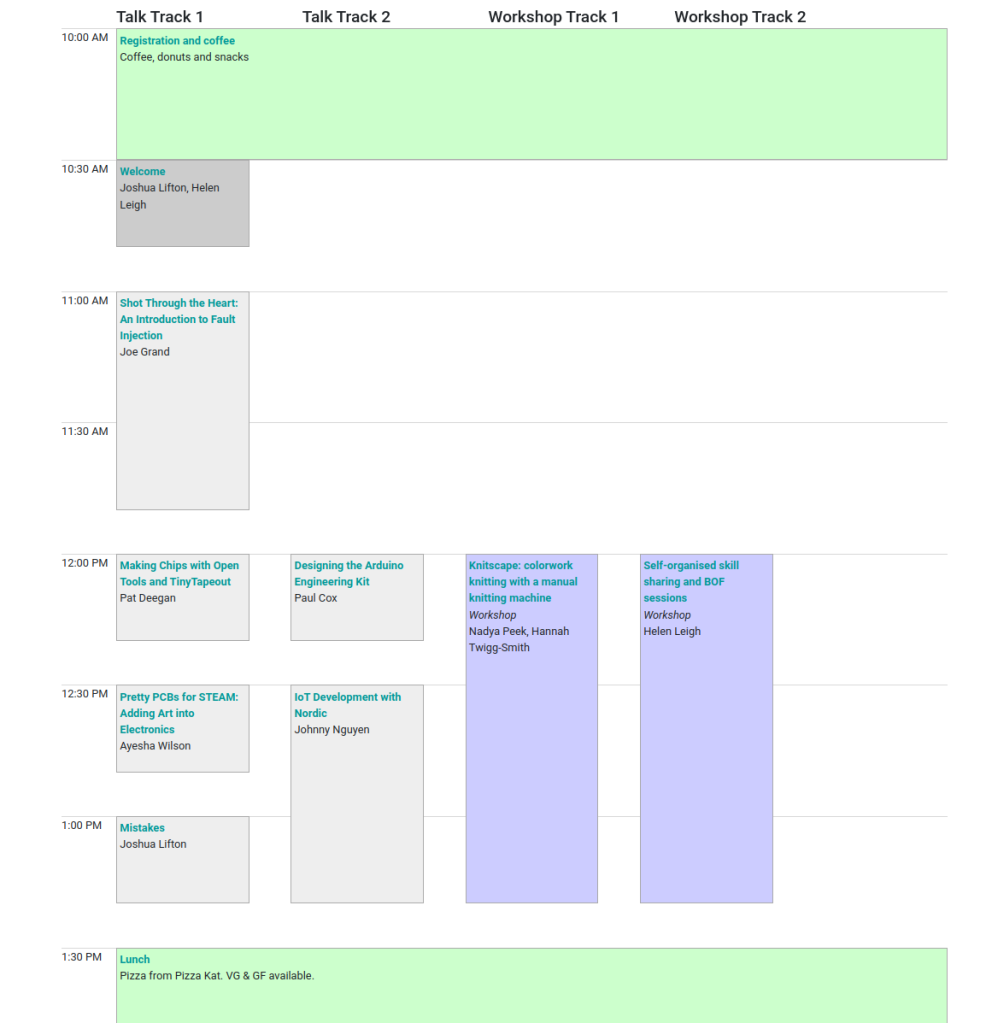

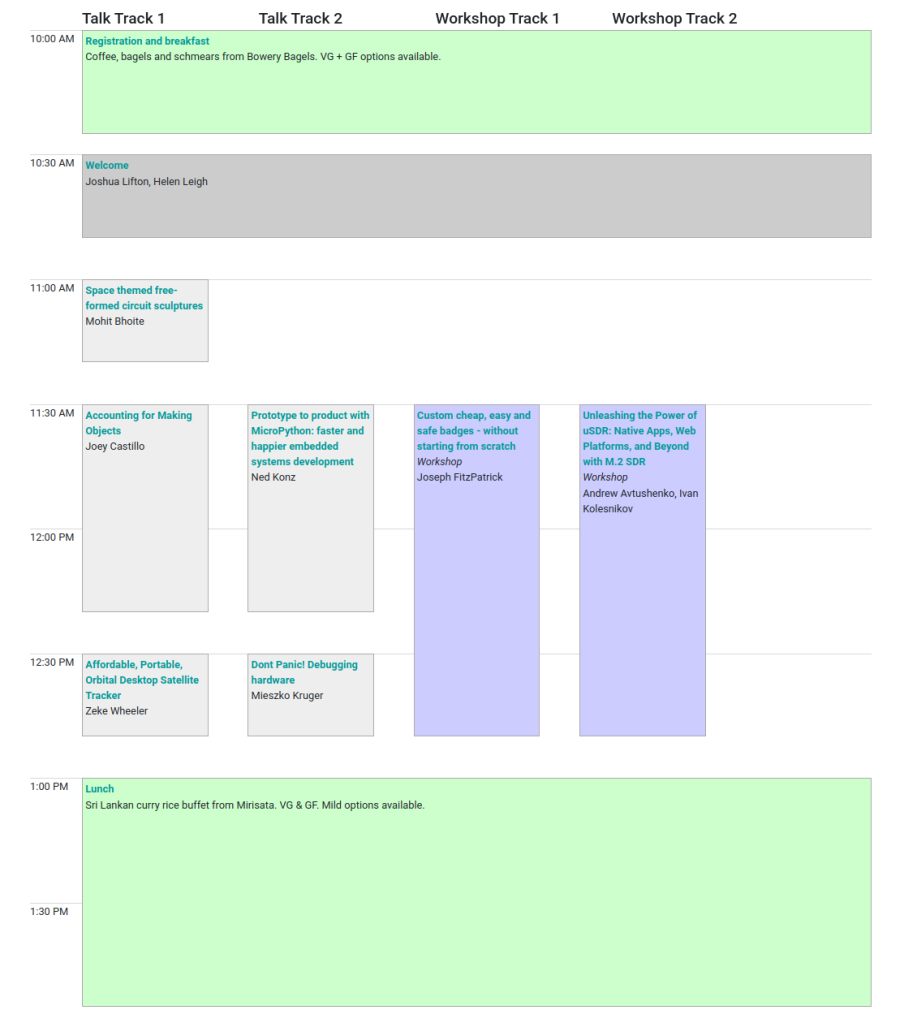

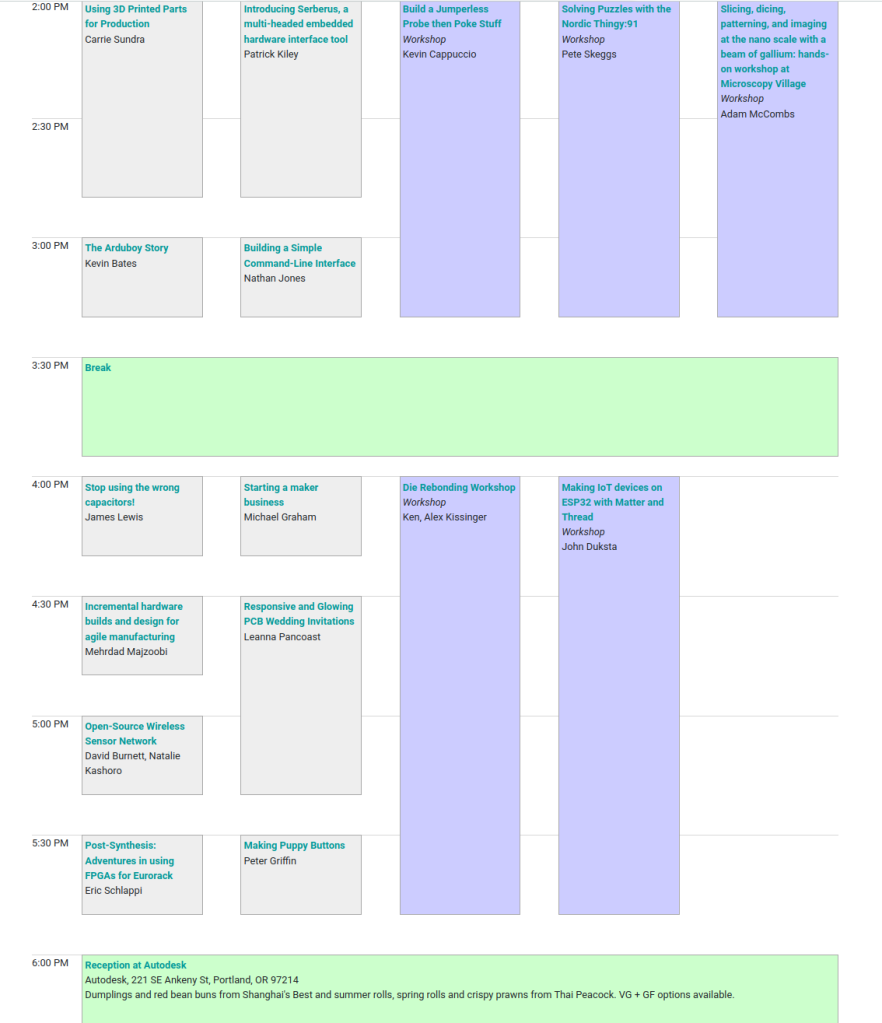

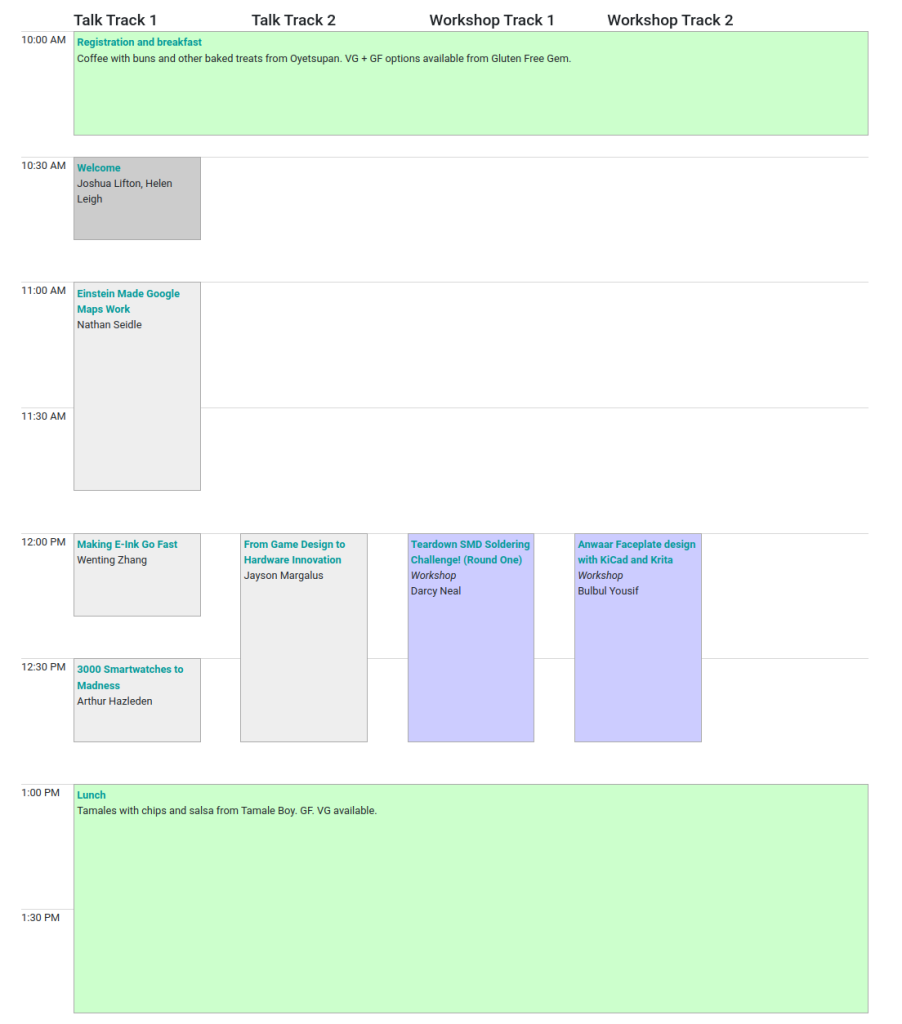

The Teardown 2024 schedule is packed with two tracks of talks and two tracks of workshops. There will will also be dozens of demos and art installations, too.

You can get hands on with a Focused Ion Beam (FIB) microscope and explore the nano world with Adam McCombs in the Microscopy Village on Friday afternoon. We are excited to hear the latest about KiCad from project leader Wayne Stambaugh on Saturday. Hardware hacking legend Joe Grand will kick off Sunday with an introduction introduction to fault injection.

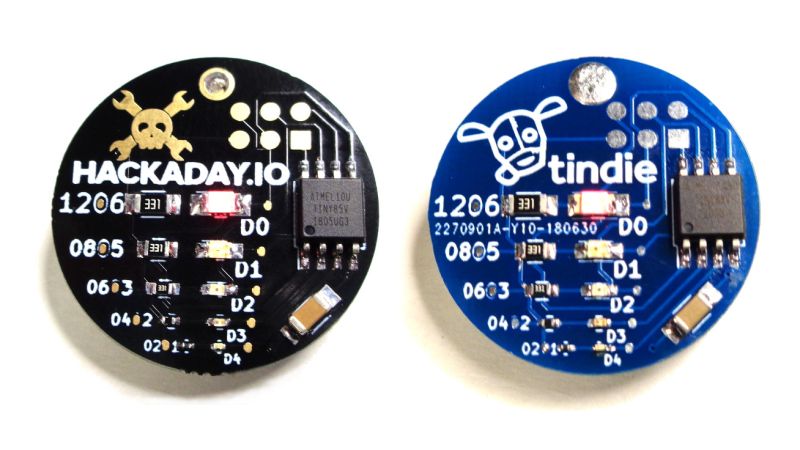

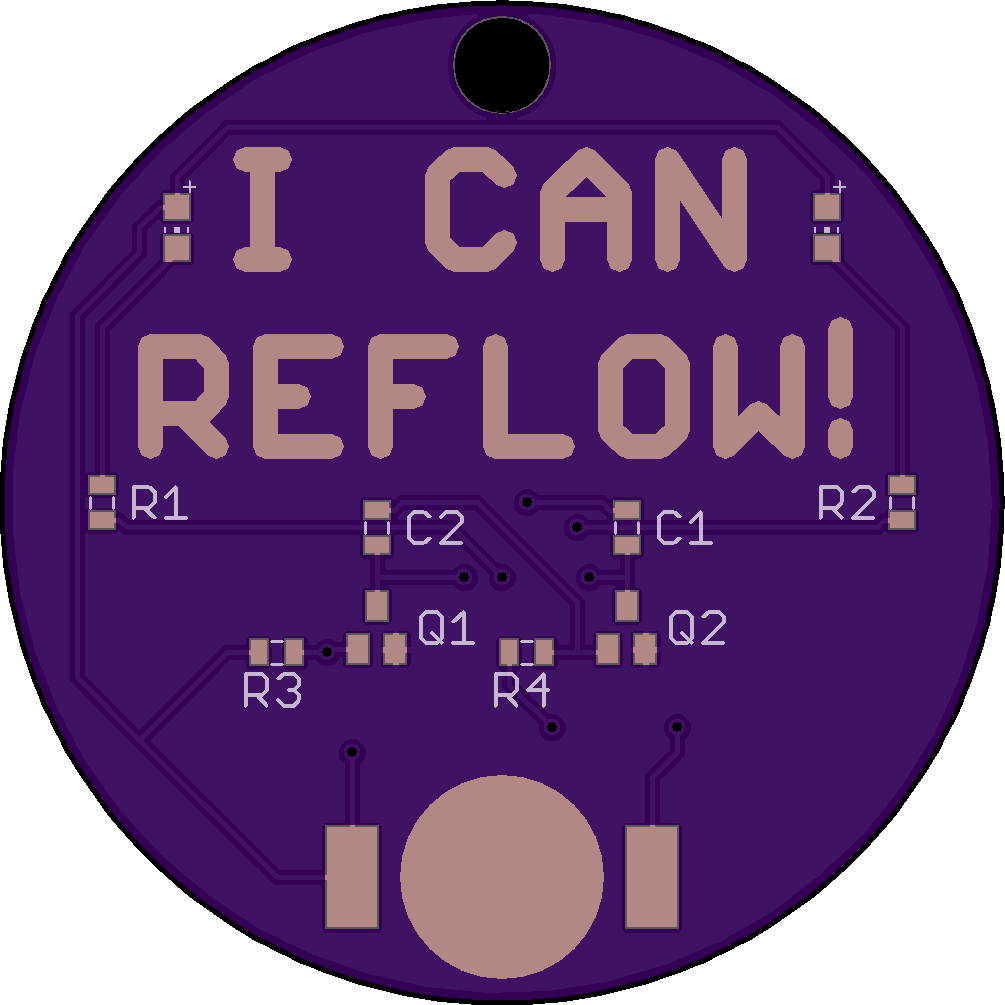

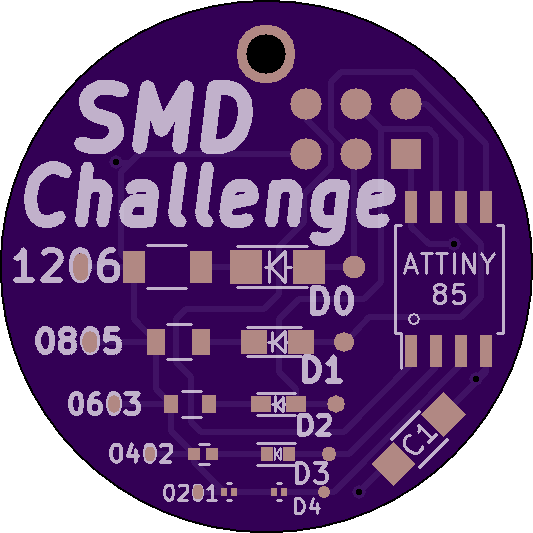

OSH Park is proud to sponsor the Teardown SMD Soldering Challenge:

Put your surface mount soldering skills to the ultimate test! Begin with the manageable 1206 package and take on increasingly tiny components, each step pushing your abilities further. This SMD project is powered by a CR2032 coin cell and an Attiny85 SOIC, offering a perfect blend of challenge and excitement. Brace yourself for the ultimate trial: hand soldering a 0201 package, a feat so intricate it will have you questioning your sanity. Are you ready to show off your skills and conquer this soldering adventure

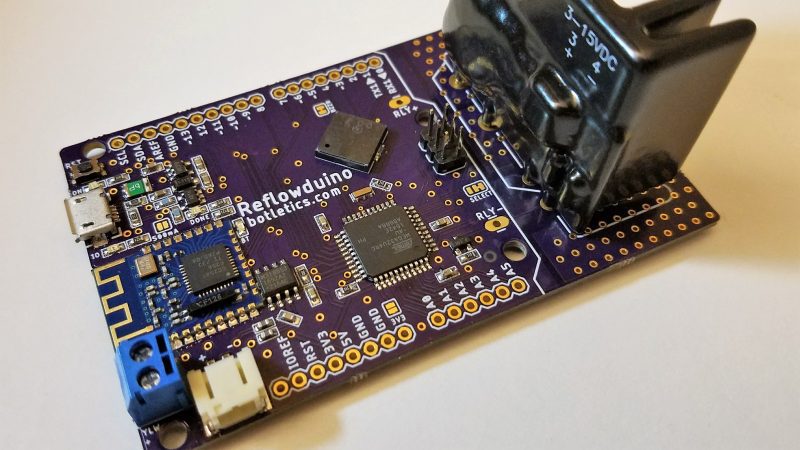

Ever wonder how to get a bare die running?

OSH Park has also sponsored an exciting Die Rebonding Workshop

- Learn decapping, x-ray inspection, and how to rebond dies

- Get your own custom hardware badge

- Hands on experience