Hackday editor Mike Szczys reviews the latest #badgelife masterpiece from AND!XOR:

For years I’ve looked forward to seeing each new unofficial hardware badge that comes out of the #Badgelife powerhouse known as AND!XOR. A mix of new and interesting components, alternate-reality game, and memes, you never know what they’re going to throw down.

A bubble pack landed on my desk on Thursday with the newest offering, the AND!XOR electronic badge built for DEF CON 29, happening this weekend as a hybrid in-person and online conference. While each previous year upped the ante on complexity and manufacturing magic tricks, it’s no surprise considering the uncertainty of both the global pandemic and global chip shortage that they took a different tack. What we have here is a badge hacking puzzle that challenges you to just figure out how to put the thing together!

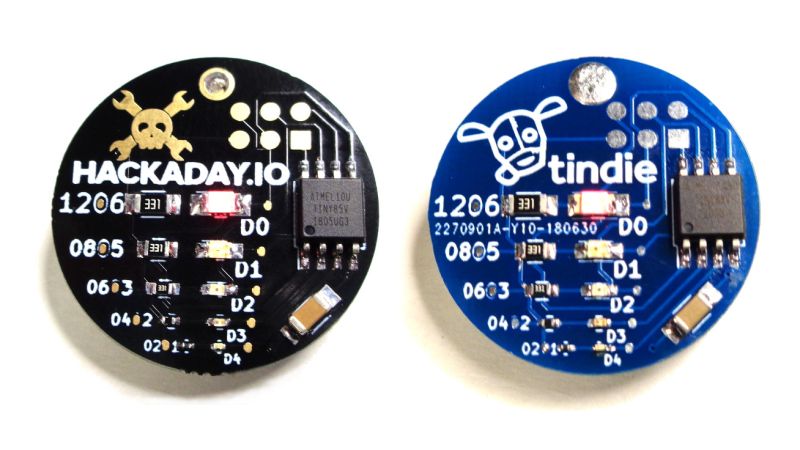

The boards themselves are obviously the “After Dark” treatment of OSH Park (and sure enough, their logo is on the back of the board). The iconic treatment uses black substrate (the board itself), clear solder mask to let the copper traces show through, ENIG plating for golden pads, and white solder mask.